The benefits of the IIoT are well documented and manufacturers around the world are investing in smart factories to improve production processes. However, most small and medium-sized manufacturing companies do not have the resources to invest millions of dollars in completely rebuilding their factories. Wherever it is possible to integrate conventional passive technology into an intelligent network, many manufacturers ask the question: “How can I upgrade my existing infrastructure?”

Bauer Gear Motor’s contribution to the “fourth industrial revolution” (Industry 4.0) began when a long-standing customer asked exactly this question, as Product Manager Simon Scharpf explains:

„Ein Kunde, mit dem wir schon vorher sehr eng zusammengearbeitet haben, bat uns, eine Alternative zu mechanischen Überlastkupplungen zu prüfen. Er suchte nach einer Lösung, die für die Drehmomentüberwachung und -steuerung von Fördersystemen effizienter wäre und idealerweise eine verbesserte Leistung im Betrieb und eine kürzere Reaktionszeit im Fall einer Drehmomentüberlastung bieten sollte. Wir haben schnell festgestellt, dass eine elektronische Lösung der beste Weg ist, um diese Anforderungen zu erfüllen, und dass diese den zusätzlichen Vorteil bietet, konkrete Daten über IO-Link in die Cloud übertragen zu können.“

Mechanical torque limiters protect the drive train by responding according to the predetermined breaking point principle when a certain torque load is reached. This is a simple but effective means of protecting applications such as belt conveyors where a foreign object can block the drive train and create unexpected loads. Most modern mechanical torque limiters also have a sensor that alerts the operator to the situation in the event of an overload. In this case, however, the mechanical coupling has to be partially dismantled and re-engaged, which increases the downtime for the operator. In addition, the mechanical system is self-contained and allows only binary control, i. H. either engaged or disengaged.

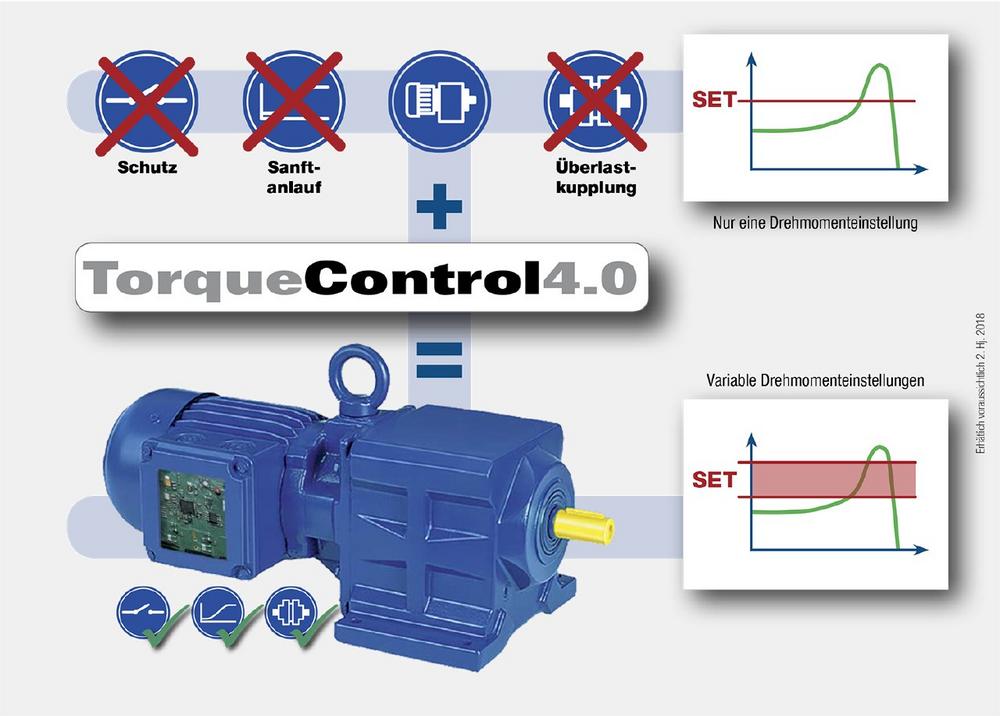

The TorqueControl4.0 solution from Bauer is an intelligent, electronic control system with which all Bauer geared motors operated on the mains can be integrated into an Industry 4.0 network cost-effectively and without a frequency converter. It enables the operator to set a flexible – but nevertheless precise – overload torque and to constantly monitor the performance. This enables preventive maintenance measures if irregularities occur. In addition, in the event of an overload, the central control can transmit the information to the production line and stop all machines as long as the overload situation is remedied. Once the congestion is removed, restarting the system over the network is a simple process.

With the option of connecting TorqueControl4.0 to the Industry 4.0 network via IO-Link, the environmental data of a standard geared motor can be monitored in real time for the first time, so that an immediate response can be made. This in turn increases the functionality and performance of the geared motor, whereby functions such as soft start and soft stop become available as well as the possibility of optimizing the magnetization of the motor independently of the load – which significantly increases the efficiency of the motor under partial load conditions.

Simon Scharpf continues:„TorqueControl4.0 ermöglicht nicht nur die Überwachung von Betriebszustand, Betriebsstunden, Temperatur und Lastzyklus, sondern kann auch eine unabhängige Abschaltung des Drehmoments bewirken und Zustandsdaten wie Strom, Spannung oder Leistung liefern. Die Parameter können so eingestellt werden, dass der Antrieb im Falle einer Überlastung innerhalb von Millisekunden abgeschaltet wird, um eine Beschädigung des Antriebsstrangs zu verhindern. Zugleich kann der Betreiber den Anlaufstrom wie bei einem herkömmlichen Sanftstarter begrenzen.

Durch die kontinuierliche Lastpunktüberwachung kann TorqueControl4.0 die Spannung so einstellen, dass der Antrieb im Teillastbereich effizient läuft. Wir gehen davon aus, dass dies den Wirkungsgrad des Motors in einigen Fällen um bis zu 25 % erhöht.“

TorqueControl4.0 is integrated in the terminal box of the motor so that the motor retains its standard protection class. The system is designed for a wide range of applications with a power requirement of up to 2.2 kW and is therefore particularly suitable for use in conveyor technology, intralogistics or in processes that start under load and require excellent energy efficiency and gentle power supply.

With TorqueControl4.0, any gear motor operated on the mains can be integrated into the IIoT without a frequency converter. The entire production line ultimately benefits from the data transmitted to the central control unit. In this way, manufacturing companies can bring technology from the 19th century to the factory of the future of the 21st century.

Captions:

Fig. 1: With TorqueControl4.0, all Bauer geared motors operated on the mains can be integrated into an Industry 4.0 network cost-effectively and without a frequency converter.

Figure 2: TorqueControl4.0 is suitable for use in conveyor technology, intralogistics or for processes that start under load and require excellent energy efficiency and gentle power supply.

Image 3: Simon Scharpf, Product Manager at Bauer Gear Motor GmbH

Seit über einem dreiviertel Jahrhundert lösen wir Antriebsprobleme überall da, wo elektrische Antriebe mit hohen Drehmomenten für Anlagen, Maschinen und Apparate gebraucht werden. Dank unserer weltweiten Niederlassungen haben Sie unser Angebot auf der ganzen Welt immer in Ihrer Nähe.

Bauer Gear Motor GmbH

Eberhard Bauer Straße 37

73734 Esslingen

Telefon: +49 (711) 3518-0

Telefax: +49 (711) 3518-381

http://www.bauergears.com

Marketing Manager

Telefon: +49 (711) 3518-276

E-Mail: info@bauergears.com

![]()