– Recognize trapped capital in production processes and convert it into value drivers

– Explore and monetize hidden potential in manufacturing processes

– Use intelligent tools to secure operational excellence for the entire production chain

– Build own production ecosystems

Recognize trapped capital in production processes and convert it into value drivers

Industries being dependent on the fulfillment of regulatory requirements like pharmaceutical and chemical are permanently confronted with complying their manufacturing environment to the latest regulations. Having always a new regulation or validation challenge ahead means constant movement, and often uncertainty in the market.

Beyond securing the competitive advantage within target markets and avoiding further pressure, manufacturing companies require a new form of business technology. Process Mining as intelligent data analysis does not only support the coverage of most relevant business targets like digitizing existing business models in manufacturing or establishing reliable solutions for modern supply chains. Especially on the monetary side, its core function is to recognize the black hole in production processes caused by sub-optimal or over-priced methods. By identifying capital trapped in production processes, this technology is getting even more attractive when users can clearly trace back the point of whenandwhere they either loose or start to earn money.

Explore and monetize hidden potential in manufacturing processes

How can Process Mining increase efficiency and productivity to boost business performance? Process Mining allows to pursue a fully optimized capacity and material planning which considers bestcase market approach and production strategies while allocating existing facilities. Thus, best economical outsourcing recommendations are provided for globally distributed production facilities. Imbalances in production volumes are avoided like holding too much of certain inventory in one place while there’s a shortage in other locations.

Process Mining also takes on the need for establishing robust supply chains where manufacturers need to be able to maintain targeted fill rates for drugs and fluids, as well as service levels in accordance with quality standards and delivery times. Manufacturing delays are eliminated that cause drug shortages, risk patient’s health and evoke considerable costs for the health care system.

Use intelligent tools to secure operational excellence during the entire production chain

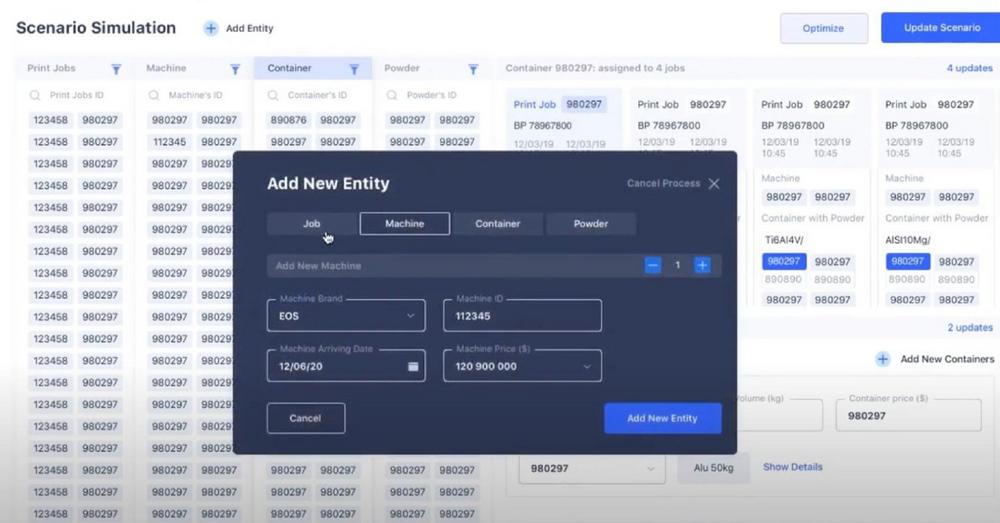

Synoptik, the intelligent software solution by Gravity Pull Systems, covers the complete production logistics and supply chain, from planning, production to fulfillment and distribution, and allows a more sophisticated and economic procedure:

Its AI-functions do not only analyze, but automatically optimize production processes, continuously recalculate the global optimum should changes occur, and provide users with a selection of data-based optimization proposals in real-time to ensure optimized pharmaceutical and chemical manufacturing. Sub-optimal or over-prized procedures are detected and made visible for process improvement.

Build own production ecosystems

Manufacturing companies can collaborate with their business partners on one common platform. Creating own ecosystems let material suppliers, production companies, regulatory bodies, customers as well as internal multi-plant facilities benefit from short information cycles, and grants clear transparency and end-to-end traceability across the entire production cycle.

Gravity Pull Systems, Inc. is the enabler of industrialization in manufacturing, with rootes originating from Additive Manufacturing. With leading AI-solutions and decades of experience, the company supports manufacturers to succeed in digital transformation within expanding technology fields. The company is headquartered in Zurich, Switzerland.

Gravity Pull Systems, Inc.

Bahnhofstrasse 6

CH8107 Buchs

Telefon: +49-173-9904996

http://gpsyst.com/

Telefon: +49 (173) 9904996

E-Mail: dagmar.bisky@gpsyst.com

![]()