By adding wireless communication to Siboni’s servo motors, a broad range of applications and flexible machine designs are enabled. As an example, the packaging process often involves rotary tables and carousels for labeling and filling machines. These machines typically require rotating the processed products to the appropriate orientation with servo motors. Such platforms can include numerous motors that require connectivity to the PLC. The rotating and high-speed nature of these makes such device connectivity restrictive, with multiple cables entailing complex and expensive deployment and maintenance. IO-Link Wireless technology provides the solution for incorporating actuators and sensors without the need for communication cables, thus reducing maintenance operations, increasing flexibility, and simplifying future add-on of multiple I/Os.

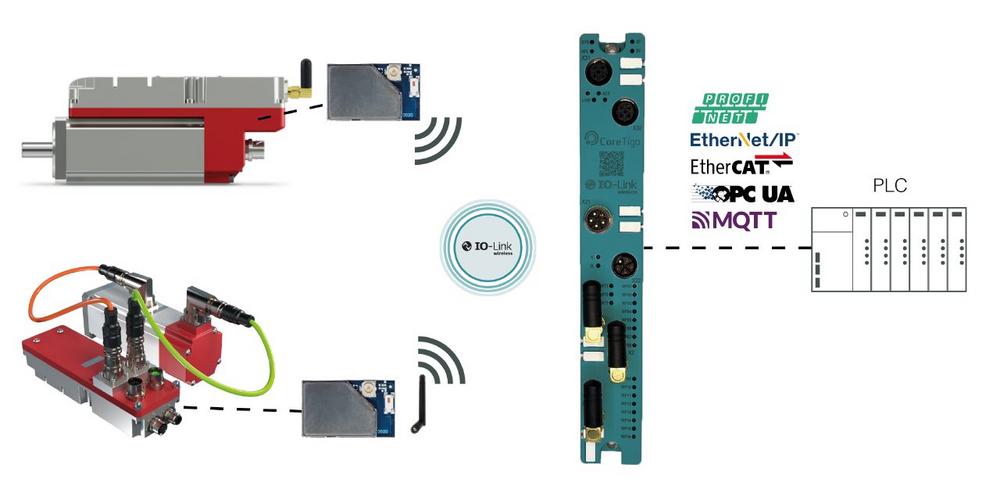

Siboni’s servo motors were enhanced by embedding CoreTigo’s IO-Link Wireless system-on-module devices (TigoAir SOM) inside the motor. The wireless servo motors communicate over the air in the most reliable and scalable manner with the IO-Link Wireless Master (TigoMaster). The Wireless Master communicates with the PLC through various popular Industrial Ethernet protocols, such as PROFINET, EtherNet-IP and EtherCAT, and other communication protocols such as OPC UA and sends back the appropriate control messages to the wireless servo motor. The IO-Link Wireless solution provides a low latency of 5msec and synchronization rates of 10’s of micro seconds, which are required for such control solutions. The solution minimizes cable connectivity and maximizes flexibility, as only a single power cable is needed to run through the center axis or slip ring of the rotating platforms even when dozens of motors are deployed.

Coupled with IO-Link Wireless, servo motors now display a new level of abilities, without trading off reliability and efficiency. Products can be processed while in constant motion for a variety of applications, all while increasing flexibility and reducing maintenance and complexity.

“In search of a solution to enable our technology to perform complex tasks while in motion, we found CoreTigo’s IO-Link Wireless offer”, Says Giuseppe Amabili, Siboni Commercial Director. “It proved to be the only solution on the market able to comply with Siboni’s high standards, thus providing new capabilities with no tradeoffs.”

“Servo motors are a great example of how deterministic real-time wireless connectivity enables new capabilities and enhances existing machinery”, Says Matteo Orlandelli, CoreTigo Country Director Italy. “Siboni and CoreTigo’s joint work is groundbreaking and will pave the way for the entire industry.”

Siboni and CoreTigo first featured this joint development at SPS 2022 in Nuremberg, Germany, as may be seen in this video. And are planning to have it displayed in many others during 2023. Stay up to date with these events at https://www.coretigo.com/events/

About IO-Link Wireless

IO-Link Wireless is a deterministic, low latency (5 msec) and low synchronization rates (10’s of micro seconds), highly-reliable and scalable universal wireless communication protocol. Based on the IO-Link IEC 61131-9 standard, it is designed specifically for factory automation, coexisting with other networks – both wired and wireless.

About Siboni

SIBONI has been offering flexible, modular and integrated mechatronic solutions for motion control in a single product for over 60 years, through DC motors, planetary gearboxes up to brushless motors with on-board and nearby electronics. The integration of CoreTigo technology within SIBONI products has allowed them to be taken to a higher level, making them more connected and improving their control and diagnostics.

SIBONI’s mission is to create customized solutions for motion control, to satisfy the wide-ranging needs of machine builders and system integrators, both in the field of industrial automation but also in all those applications, such as electric traction, where it is required low voltage power supply through batteries.

SIBONI’s know-how not only allows you to design completely dedicated products, but also to follow the entire life cycle of the product, thanks to the production site in Forlì (Italy) and a proximity supply chain that guarantees quality components and an industrial process flexible, respecting the high quality standards of its products.

CoreTigo enables faster and more flexible manufacturing by providing high-performance machine digitalization, wireless connectivity and edge solutions for machine builders, system integrators and industrial equipment manufacturers. CoreTigo’s products enable the design and retrofit of machines and production lines that were not possible before. These solutions increase flexibility, adaptivity and modularity, resulting in cost effectiveness, increased productivity and downtime reduction. Embraced by industrial leaders, CoreTigo’s solutions are based on the IO-Link Wireless global standard, which is fit for harsh factory environments and motion control applications, providing the most reliable wireless connectivity for millions of sensors, actuators and industrial devices worldwide.

CoreTigo

Giborei Israel 5

IL4250405 Netanya

Telefon: +972-52-8536663

http://www.coretigo.com

Chief Strategy & Marketing Officer

Telefon: +972.54.779.0466

E-Mail: gdaniely@coretigo.com

Marketing Manager

E-Mail: rglas@coretigo.com

![]()