To enhance global sustainability, the automotive industry is rapidly expanding the development and production of electric and hybrid vehicles. However, the maximum achievable range on a single charge remains a concern for consumers. As a result, automakers are pursuing smaller and lighter components, and developing faster, higher output motors. Accordingly, the bearings used in powertrains, especially in electric motors, are being subjected to increasingly higher speeds and performance demands.

Bearing rotation during high-speed operation can cause problems such as grease deterioration due to elevated operating temperatures, resulting in bearing seizure/failure. Higher speeds can also lead to the bearing cage being deformed or destroyed by centrifugal forces.

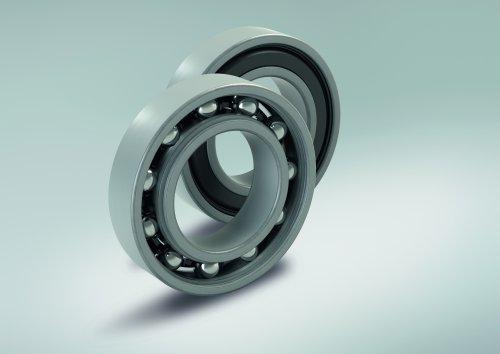

To help counter these issues, the new NSK bearing is filled with a proprietary grease that reduces heat generation at high rotational speeds, prolonging both grease and bearing life, and reducing the risk of seizure compared with conventional products.

In addition, a newly developed cage is deployed with retainer tabs that are not only thinner and lighter, but reduce the potential for cage deformation or breakage. This innovation is supported by a new design of cage base (spine) and a newly developed cage material made from high-rigidity resin, which offers further heat resistance at the elevated speeds found in EV motors.

The combination of proprietary NSK grease and newly developed cage enables bearing operation at dmN(1) = 1.4 million. To provide a practical example, this world-leading measure of rotational performance means one of NSK’s new 35 mm bore diameter bearings can operate reliably at speeds of 30,000 rpm.

As a result of this advance in bearing technology, automotive customers can develop and implement electric motors that operate at significantly higher speeds. High motor output contributes to the utilisation of smaller motors, reduced vehicle weight and increased space for other components, such as more battery cells, for example, or the use of a larger vehicle interior. In turn, lower fuel consumption, extended vehicle range and/or improved comfort can be achieved.

Looking ahead, NSK is continuing its development efforts and expects to announce bearings capable of dmN = 1.6 million by the end of 2020.

(1) dmN: A measure of bearing rotational performance. The product of bearing pitch diameter (dm) and rotational speed (N).

NSK Europe Ltd. is the European organisation of the Tokyo-based bearing manufacturer NSK, which was founded in Japan in 1916 and today employs nearly 31,000 people in its worldwide operations. The products and solutions provided by the industrial and automotive supplier can be found wherever things move. In addition to nearly all types of rolling bearings, the company’s portfolio includes housed bearings, linear technology, wheel bearing units, transmission and engine bearings and steering systems. The company is oriented to perfection in all of its business activities. Its aim is quality leadership in its industry, which it strives for through a continuous process of improvement, excellent product development, optimised production processes and customer-oriented service processes. In fiscal year 2019, the more than 4,400 employees of NSK Europe Ltd. generated sales of over € 920 million.

www.nskeurope.com

NSK Deutschland GmbH

Harkortstrasse 15

40880 Ratingen

Telefon: +49 (2102) 4810

http://www.nskeurope.de

Telefon: +49 (2102) 4811280

E-Mail: pilath-m@nsk.com

![]()